The Carbon is a dream skate for many skaters, yet it is also a high class product made of the most expensive materials used on an aggressive skate. With the desire to make this new skate available to a lower budget we took the time to talk to companies about making special plastic blends that could serve to re-create the Carbon effect at a more affordable price.

After two meetings with DuPont we were told that they had the perfect plastic for us:

- DuPont™ Hytrel® TPC-ET Thermoplastic polyester elastomer;

- Hytrel® – A thermoplastic and elastomer in one.

Hytrel® thermoplastic polyester elastomers provide the flexibility of rubber, the strength of plastic and the processibility of thermoplastics.

Hytrel® is also available in a full range of Shore D hardness (30D to 82D). Special grades are heat stabilized, flame retardant and blow molded. Concentrates include black pigments, UV protection additives, hydrolysis resistant additives, heat stabilizers and flame retardants.

NEW – Hytrel® RS renewable sourced thermoplastic elastomers can help reduce environmental footprint without compromising performance.

New grades containing 35% to 65% of renewable sourced material are in development and early tests show they grant the same performance and processing characteristics of original Hytrel®.

Ideal specs:

Hytrel® is ideal for parts requiring excellent flex fatigue and broad use temperature. It resists tearing, flex-cut growth, creep and abrasion. It offers strength and stiffness plus outstanding toughness while resisting hydrocarbons and many other fluids. Hytrel® can be processed easily by conventional thermoplastic processes, such as injection molding, blow molding, calendaring, rotational molding, extrusion and meltcasting.

We made our first tests with this material injection into a one piece plastic skate and tested it, advancing to test a variety of hardness until we found the perfect one.

We also redesigned the internal structure making a fully integrated cuff with built-in flex and support zones. The resulting product is made of a new patented construction that grantees satisfaction on all demands of an aggressive skate.

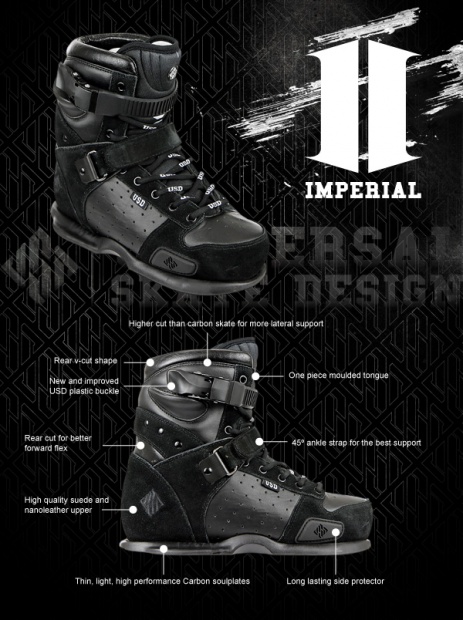

- Shoe-like fit.

- Shoe-like appearance.

- 35% less volume than that of a standard hard boot.

- 25% less weight than a standard hard boot.

- Total control with direct power transfer.

- Higher cut than Carbon skate with more lateral support.

- Rear V-cut

- Includes quality Sifika Shock absorber

- New Powerslide Slimfit innersole

- Neoprene and Microfiber interior lining for optimum control, last and comfort.

- Compatible with the Carbon soul plates, thin, light, high performance design.

- Strong nanoleather upper